After a long hiatus, I’m back to share some of my favorite holiday cards. I’m especially fond of folded cards, and I’m not talking about a standard side-fold card! I love a good z-fold or wallet card, especially when dealing with multiple photos and/or text. The first example is from the 2021 new year. I’d been doing this client’s cards since her boys were young, and all the sudden they were grown up and graduating from high school! We created a stunning final holiday card featuring her boys’ kindergarten photo next to their senior photo, and well wishes as they venture into college life. I’m kind of sad to see it come full circle, but it was a wonderful ride!

Front panel of new year’s card with textured background.

View of card from above showing z-fold format.

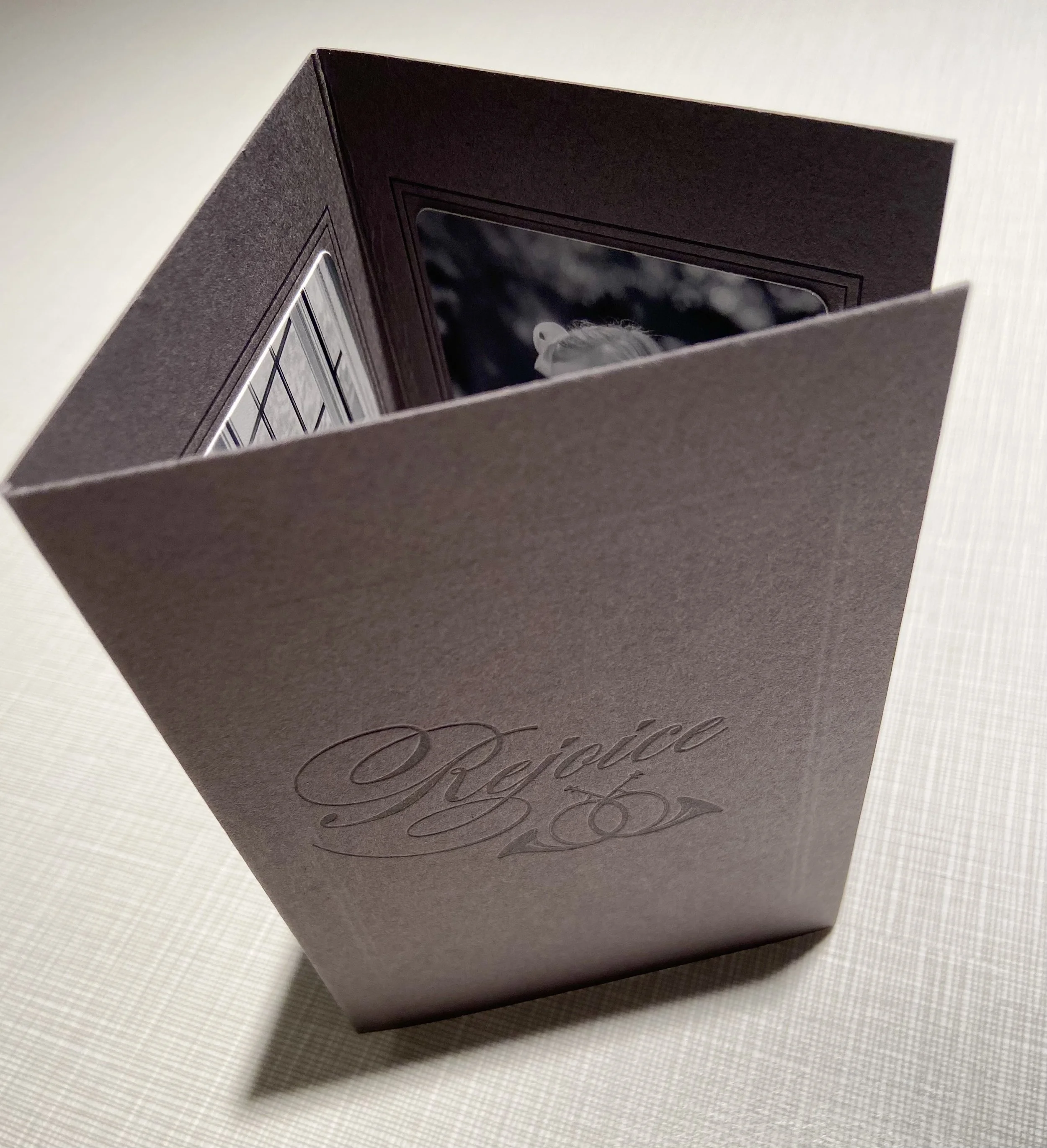

Next up is a christmas card from several years ago that stands out as a favorite. I adore working with this client every year to come up with something unique. It was difficult to decide on photos of her girls, so we used all three! The wallet format allows printing on the front panel, and immediately on the right when you first open. As you continue to open the final flap you have a gallery of all three photos. The card size is small and intimate, and tone on tone printing adds an elegant touch. It’s perfection!

view from above of wallet fold card with printing on front, and three photos mounted inside.

The last example is from the 2021 holiday season and is another z-fold card. I love the simplicity and clean lines of this design. I wanted the b/w photography to stand out, so kept it simple. My client wanted to feature her animals on the card this year in a separate photo, so we decided to do a folded style.

Small square z-fold card featuring two photos and clean text.

When you’ve been creating cards for clients as long as I have, it can get tricky to introduce something new and different. You can certainly get into a rut! I encourage clients to switch it up each year, whether it’s doing a folded card instead of a flat one, or color instead of b/w (that goes for photos too). Have fun with it!